While working with GPS RTK and setting up my own RTK base station I thought it would be cool to use this technology in a real robot and make it drive between the waypoints. I know it’s nothing new as Ardupilot can do that and there are a lot of videos on YouTube that show similar robots. But how many of them are properly documented? How many of them can you just easily replicate? For me, it’s always:

- Build a cool project.

- Create documentation that is as cool as the project.

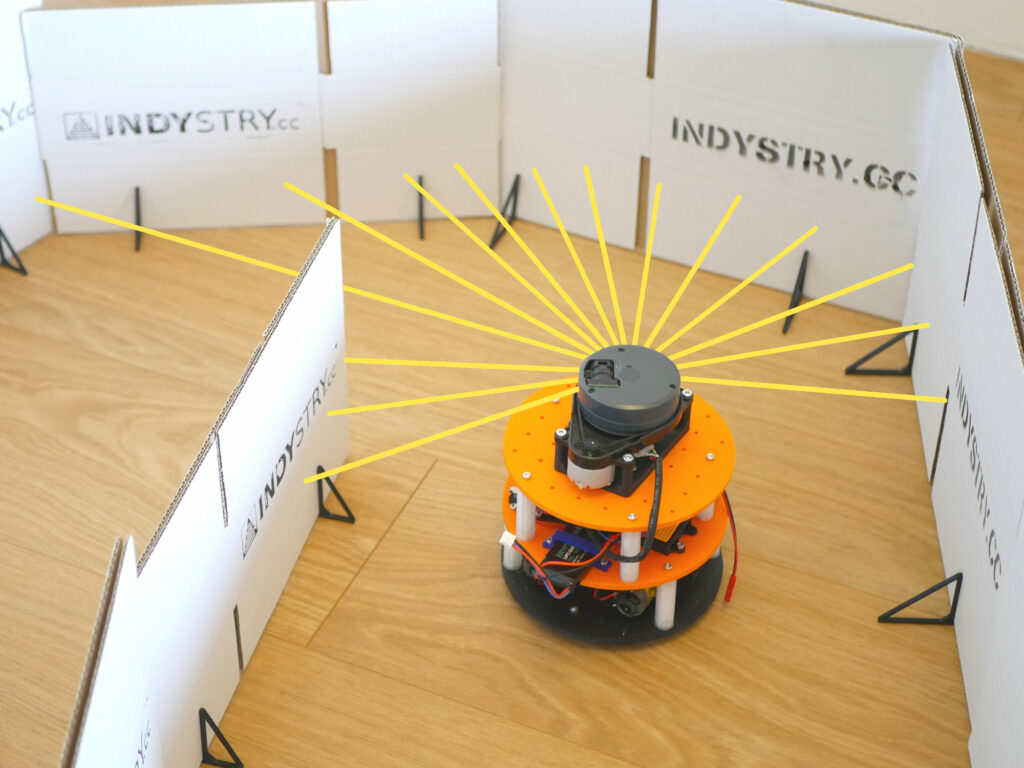

With this approach and knowing that I would like to implement GPS RTK on my IndyMower lawn mowing robot I started thinking about a bigger robot chassis that I could use for experiments and learning. With that in mind, a big 3D-printed chassis on track was born.

The design of the 3D printed platform

The design phase started with a simple drawing that was then converted by a freelancer on Fiverr to a 3D design. The design was decent but required a few adjustments and after a while, I decided to do a few things differently which meant I had to redesign a big part of this project.

Most of the parts were printed with PETG and some of them with PLA. I used Bambulab printers to print all of the parts.

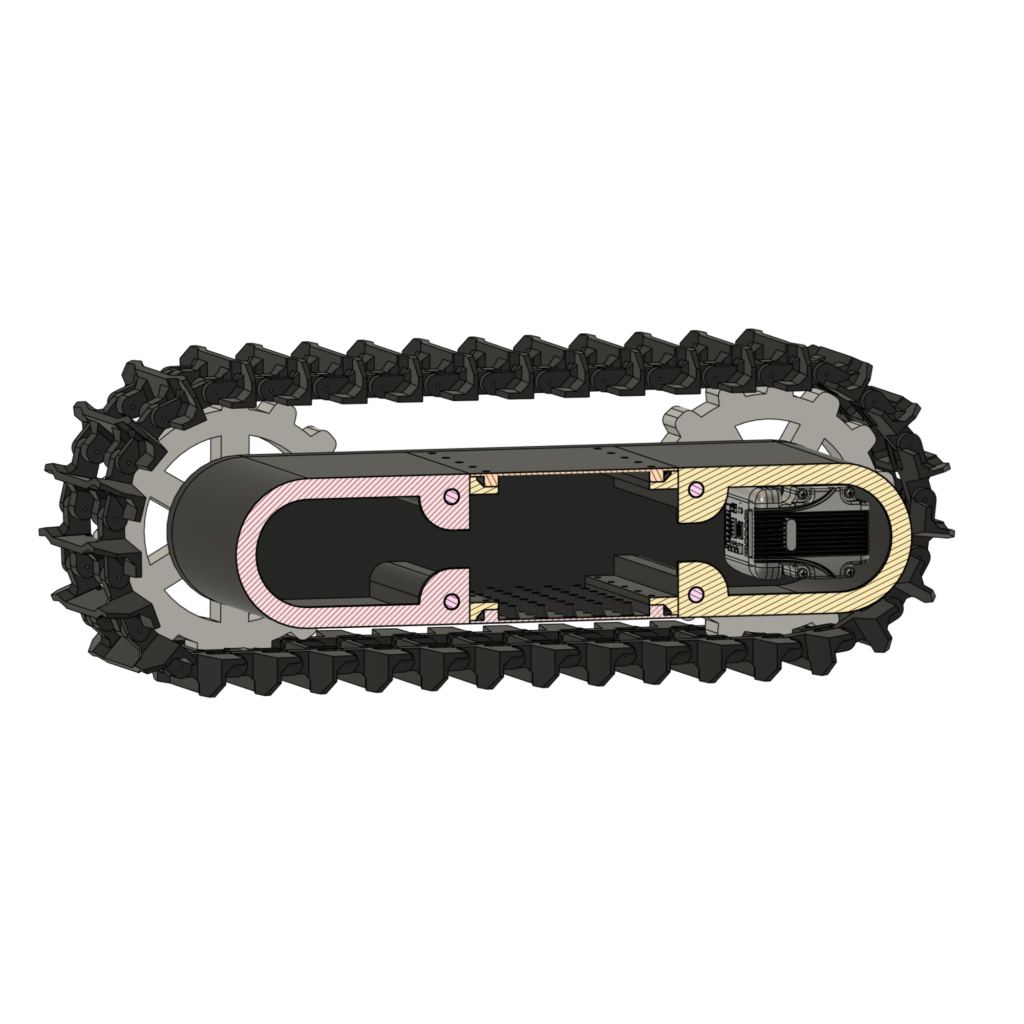

The tracks are printed as separate pieces that are later joined with a piece of filament that is secured on both ends with a hot tool forming something similar to a rivet. It works quite well and is very strong. There are also plywood plates on the sides that hold wheels and motors. The 3D-printed parts of the body are sandwiched between the two plywood plates and connected with M10 threaded rod. Thanks to that the body of the robot is quite durable despite being made mostly out of plastic.

Powerful motors for the robot platform? Servos or wiper motors?

For the motors, I used Leadshine iSV2-CAN6020V24G – fancy servo motors that communicate via CanOpen with Arduino. The design is easy to adjust to any similar-looking motor if you want to. I realized that these motors do not have a gearbox and therefore they do not have high torque required for such a robot. For that reason I am thinking about switching to wiper windshield motors as they seem to be an inexpensive and robust alternative.

Here is the cross-section view of the chassis:

If you want to build a robot chassis yourself, you can grab the design files (3MF, STEP, STL, and F3D) from my store:

Video about the project

You can also take a look at this video, there are a lot more details about the chassis as well as GPS RTK and the future plans for this project: